Vacuum induction melting furnace is one of the most widely used equipments in vacuum metallurgy field. It has been proved that a considerable proportion of the alloys and special steels needed by aerospace, missile, rocket, atomic equipment and electronic industries are produced by vacuum induction melting furnace. For example, when the nickel base, cobalt base and iron base superalloys are smelted by vacuum induction melting furnace, their thermal and mechanical properties are significantly improved. Like stainless steel, heat-resistant steel, ultra-high strength steel, tool steel, bearing steel, as well as magnetic materials, elastic alloys, expansion alloys, almost all use vacuum induction melting furnace to melt, in order to ensure material properties and quality

Technical parameters of vacuum induction melting furnace:

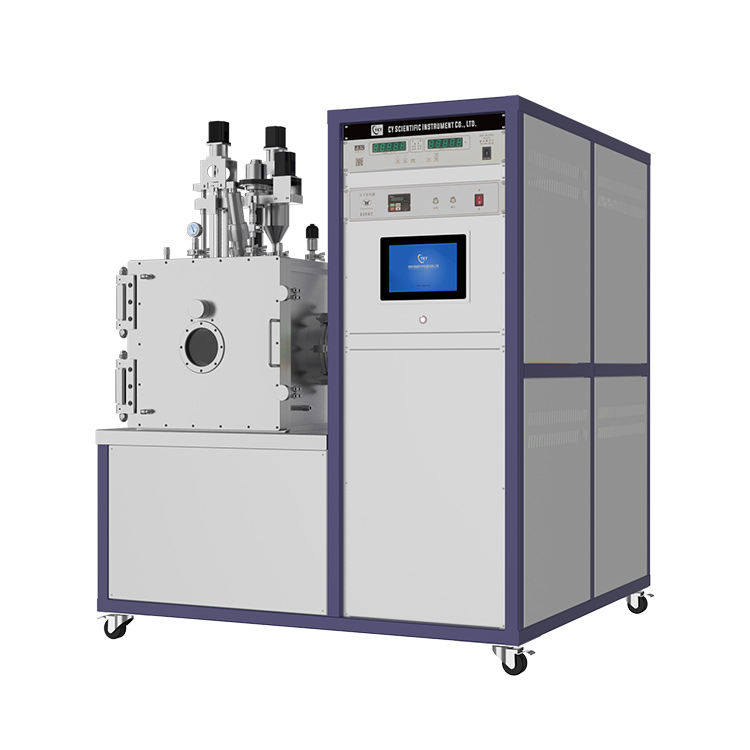

Product name | 1800 degrees 1Kg vacuum induction melting furnace |

Product model | CY-IV400-35KW-SS |

Smelting weight | 1Kg |

Maximum temperature | 1800℃ |

Induction power supply | Frequency | 30-80kHz |

Power | 35KW |

Vacuum chamber | Material | 304 stainless steel |

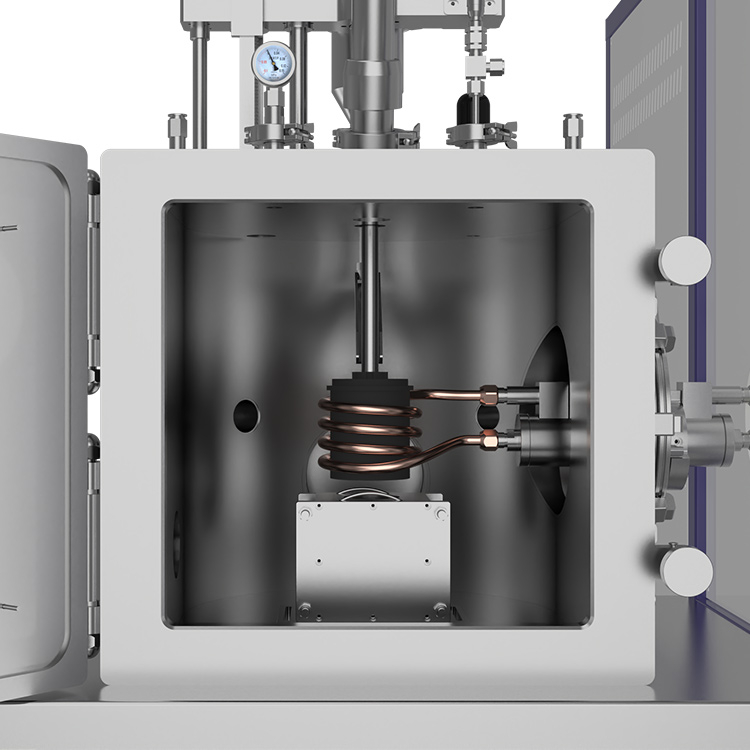

Structure | Double-layer water-cooled sandwich structure |

Dimensions | φ400mm x H400mm |

Cooling system | Water-cooled electrode, water-cooled cavity, water-cooled mold |

Observation window | Main observation window diameter φ120mm Top cover with feed port |

Mechanical stirring | Electric stirring 5-100rpm |

Accessories | Infrared temperature measurement and vacuum funnel |

Water cooling interface | φ10mm quick-connect plug |

Vacuum interface | ISO160/KF40 |

Exhaust interface | KF16 |

Power supply | 380V |

Casting system | The right side of the cavity is equipped with a dumping device for pouring after smelting Casting mold size: φ60mm x 89mm Mold type: water-cooled copper mold |

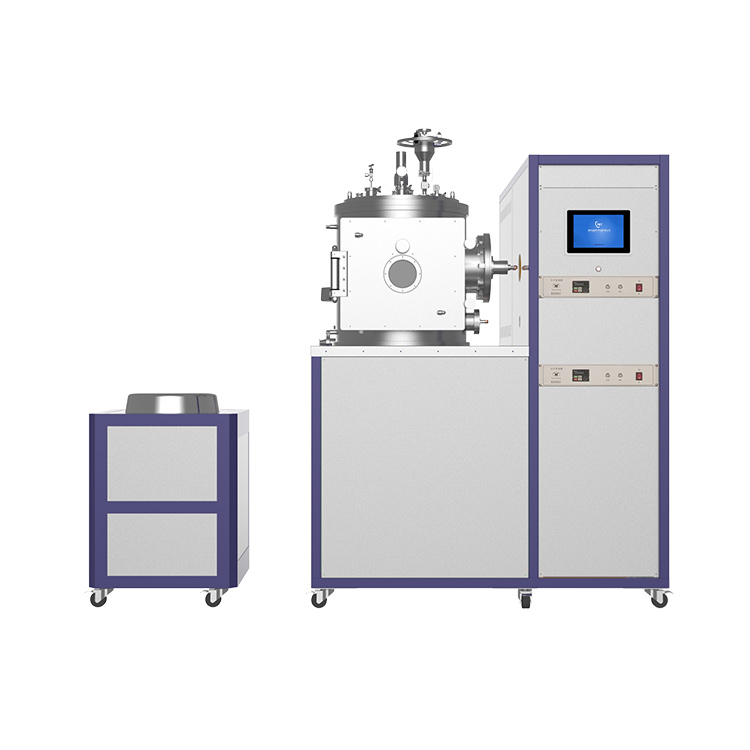

Vacuum system | Bipolar rotary vane pump, pumping speed 4.4L/s |

Feeding tank | After metal A is melted, add block B to the melt of A without opening the furnace door |

Induction heating system | Induction coil: inner diameter 100mm, height 80mm |

Temperature control | Automatic control |

Other | Supply voltage | 380V |

Total power | 40KW |

Weight | 600kg |

Total dimensions | 1340mm x 1240mm x 1650mm |